When designing a new electronic product, one of the most critical steps is creating a printed circuit board (PCB) that connects and supports the various components of the device. Printed Circuit Board Assembly (PCBA) services play a vital role in this process, particularly for those who are prototyping new products. This guide will walk you through the basics of PCBA services and how to use them effectively for your prototype.

What is Printed Circuit Board Assembly (PCBA)?

Printed Circuit Board Assembly (PCBA) refers to the process of mounting electronic components onto a PCB to create a fully functioning circuit. The PCB itself is a flat board made of non-conductive material, typically fiberglass, with conductive pathways (traces) that link various components such as resistors, capacitors, and microchips.

PCBA involves several processes, including:

- Soldering: Attaching components to the board using a combination of heat and solder.

- Surface Mount Technology (SMT): A method where components are mounted directly onto the surface of the PCB.

- Through-Hole Technology (THT): Involves inserting components through holes in the PCB and soldering them to the other side.

For prototypes, the complexity of your design will determine the type of assembly required. PCBA services can accommodate a range of options, from simple boards to complex, multi-layer designs.

Why Use Printed Circuit Board Assembly Services for Prototyping?

Prototyping is a critical step in product development, and working with a professional printed circuit board assembly service provider offers several advantages:

- Expertise and Quality Control: PCBA companies have the experience to produce high-quality boards with reliable assembly, ensuring your prototype functions as intended.

- Speed and Efficiency: By outsourcing PCBA services, you can save time and speed up the prototyping process, allowing you to focus on other aspects of product development.

- Cost-Effectiveness: Using an external PCBA service provider can often be more cost-effective than handling assembly in-house, especially when you’re working with a limited number of prototypes.

- Access to Advanced Technology: Professional PCBA services have access to the latest equipment and technologies, which can be crucial for complex designs.

How to Choose the Right PCBA Service for Your Prototype

Selecting the right printed circuit board assembly service is crucial to ensuring the success of your prototype. Here are a few key factors to consider:

1. Prototyping Capabilities

Not all PCBA companies are equipped to handle prototypes, especially if your design is unique or requires specialized components. Make sure the service provider has experience with prototypes and is capable of working with the specifications of your design.

2. Quality Assurance Processes

A reliable PCBA provider should have robust quality control processes in place. Look for services that offer testing such as automated optical inspection (AOI), X-ray inspection, and functional testing to ensure your prototype is free from defects.

3. Experience and Reputation

A provider with a strong track record of working with startups and product designers is likely to have the necessary expertise to handle your project. Research online reviews, ask for references, or request samples of their previous work to gauge their capabilities.

4. Lead Time and Turnaround

When working on a prototype, time is often of the essence. Ensure the PCBA provider can meet your timelines and offers fast turnaround without compromising on quality.

5. Cost Considerations

While it’s important to stick to a budget, don’t sacrifice quality for a cheaper price. Make sure the service offers competitive pricing that aligns with the complexity of your design.

The PCBA Process for Prototypes

Once you’ve selected a PCBA service, understanding the process can help you prepare and manage expectations. Here’s a basic breakdown of the steps involved:

- Design and File Preparation: You will need to provide the service provider with your design files, which typically include Gerber files, Bill of Materials (BoM), and schematic diagrams. These files detail the layout of the PCB and the components to be used.

- Component Sourcing: The PCBA service will source the necessary components for your prototype. This includes procuring the components, which can sometimes take time if parts are rare or specialized.

- PCB Fabrication: The service provider will create the PCB based on your design files. This involves the fabrication of the board itself, including etching the traces, drilling holes, and applying the copper layers.

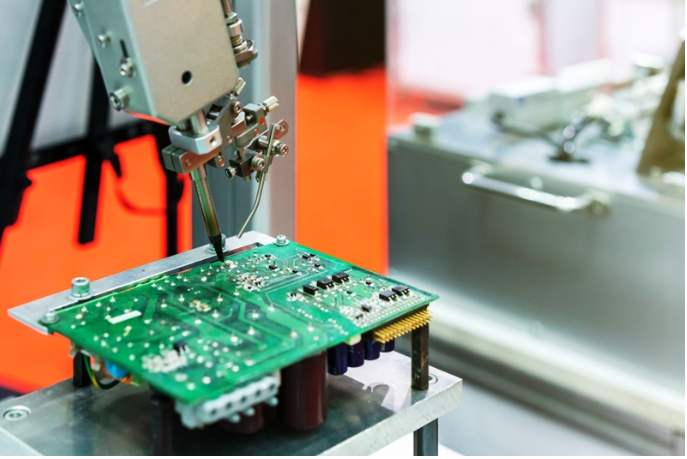

- Assembly: This is the step where the electronic components are attached to the PCB using either SMT or THT, depending on your design specifications.

- Testing and Quality Control: After assembly, the prototype will undergo rigorous testing to check for functional performance, soldering issues, and any design flaws.

- Delivery: Once everything has been tested and approved, your assembled PCBs will be delivered. You can then move on to further stages of product development.

Conclusion

Using Printed Circuit Board Assembly services for your prototype can save you time and reduce the complexity of the product development process. By partnering with a reputable PCBA service, you can ensure your prototype is assembled efficiently and to a high standard. With the right provider, you’ll have a high-quality prototype that will serve as a solid foundation for the next stages of your project. Whether you’re creating a simple or complex design, investing in professional PCBA services is a wise decision to help bring your ideas to life.